Introduction

Understanding EGR Solutions industry continually seeks ways to improve vehicle performance while minimizing environmental impact. The Exhaust Gas Recirculation (EGR) system is a critical innovation in this pursuit. This technology, designed to reduce nitrogen oxide (NOx) emissions, plays a pivotal role in modern vehicles. In this article, we delve into the intricacies of EGR solutions, exploring how they enhance car performance and contribute to a cleaner environment.

What is EGR?

The Basics of EGR

Exhaust gas recirculation (EGR) is a method used to reduce NOx emissions from internal combustion engines. The EGR system works by recirculating a portion of an engine’s exhaust gas back to the engine cylinders. This process reduces the amount of oxygen available in the combustion chamber, thereby lowering the combustion temperature and, consequently, the formation of NOx.

Historical Background

EGR technology has been in use since the 1970s initially introduced as a response to stringent emission regulations. Over the decades, advancements in EGR systems have significantly improved their efficiency and reliability, making them a standard feature in most modern vehicles.

How EGR Systems Work

Components of an EGR System

An EGR system typically comprises several key components, including the EGR valve, EGR cooler, EGR control solenoid, and the associated piping and sensors. Each component plays a crucial role in ensuring the system operates effectively.

- EGR Valve: This valve regulates the flow of exhaust gases into the intake manifold.

- EGR Cooler: Cools the recirculated exhaust gases before they re-enter the combustion chamber, enhancing efficiency.

- Control Solenoid: Manages the opening and closing of the EGR valve based on the engine’s operating conditions.

- Sensors: Monitor various parameters, such as temperature and pressure, to optimize the EGR system’s performance.

Operation of EGR

The EGR system operates by redirecting a portion of the exhaust gases back into the engine’s intake manifold. When the EGR valve opens, exhaust gases flow through the EGR cooler (if present), where they are cooled before entering the intake manifold. The cooled exhaust gases mix with the incoming air-fuel mixture, reducing the overall combustion temperature and thereby decreasing NOx formation.

Types of EGR Systems

High-Pressure EGR (HP-EGR)

High-pressure EGR systems recirculate exhaust gases from the exhaust manifold back into the intake manifold. This type of EGR is typically used in diesel engines due to its effectiveness at reducing NOx emissions under high-load conditions.

Low-Pressure EGR (LP-EGR)

Low-pressure EGR systems, on the other hand, recirculate exhaust gases from a point after the diesel particulate filter (DPF) or catalytic converter. This system is often used in gasoline engines and offers improved efficiency by reducing pumping losses and enhancing fuel economy.

Benefits of EGR Systems

Environmental Benefits

The primary environmental benefit of EGR systems is the significant reduction in NOx emissions. NOx gases are a major contributor to air pollution and the formation of smog and acid rain. By lowering the combustion temperature, EGR systems minimize the production of these harmful gases, contributing to cleaner air and a healthier environment.

Enhanced Engine Performance

Contrary to the common misconception that EGR systems reduce engine performance, they can actually enhance it. By reducing the combustion temperature, EGR systems help prevent engine knocking, improve combustion efficiency, and reduce the formation of harmful particulates. Additionally, modern EGR systems are designed to operate seamlessly with other engine management systems, ensuring optimal performance.

Improved Fuel Economy

EGR systems can also contribute to improved fuel economy. By recirculating exhaust gases, the engine requires less fresh air, reducing the pumping losses associated with drawing in fresh air. This results in better fuel efficiency, especially in diesel engines where high-pressure EGR systems are commonly used.

Challenges and Solutions

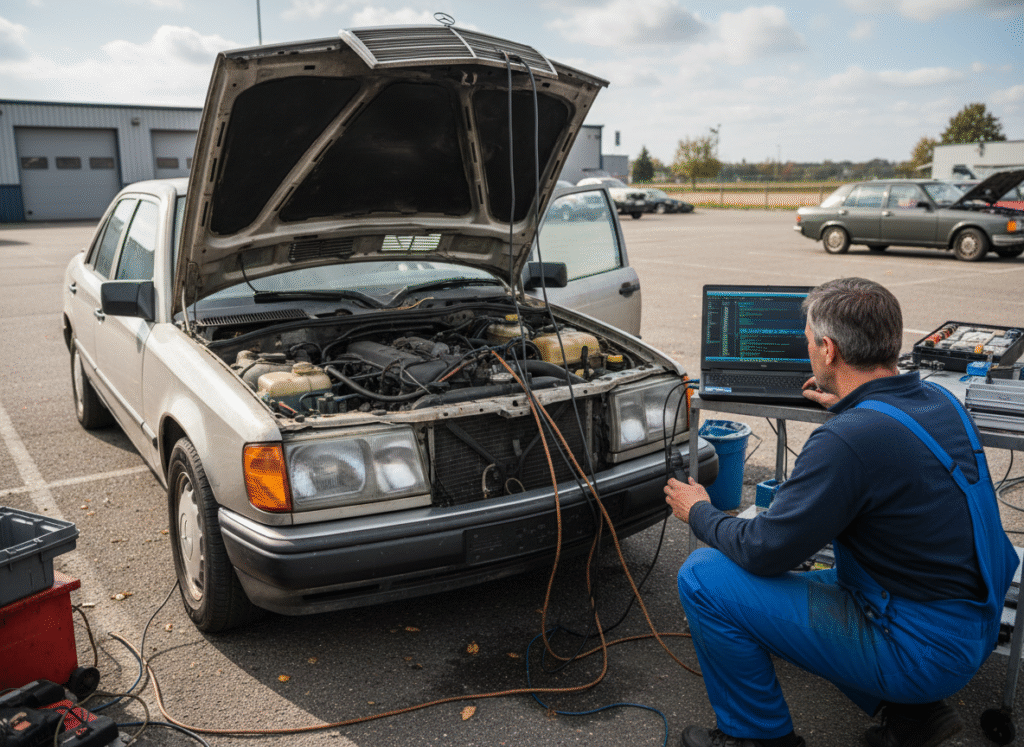

Common Issues with EGR Systems

While EGR systems offer numerous benefits, they are not without challenges. Some common issues include:

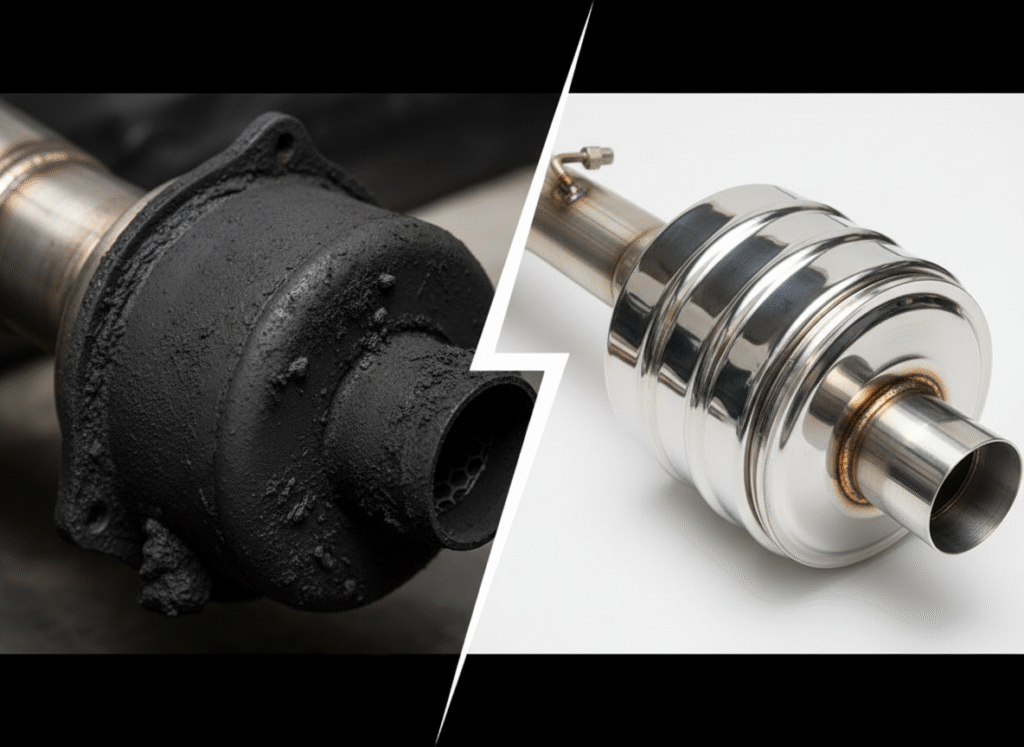

- Carbon Build-Up: Over time, carbon deposits can accumulate in the EGR valve and cooler, leading to reduced efficiency and potential system failure.

- Valve Sticking: The EGR valve may become stuck open or closed, causing rough idling, decreased performance, and increased emissions.

- Cooling System Failures: In systems with an EGR cooler, leaks or failures can lead to coolant contamination and engine overheating.

Addressing the Challenges

To mitigate these issues, regular maintenance and cleaning of the EGR system are essential. Using high-quality fuels and lubricants can also help reduce carbon build-up. Additionally, advancements in EGR technology, such as the development of more robust materials and improved designs, have enhanced the reliability and longevity of these systems.

EGR Systems in Modern Vehicles

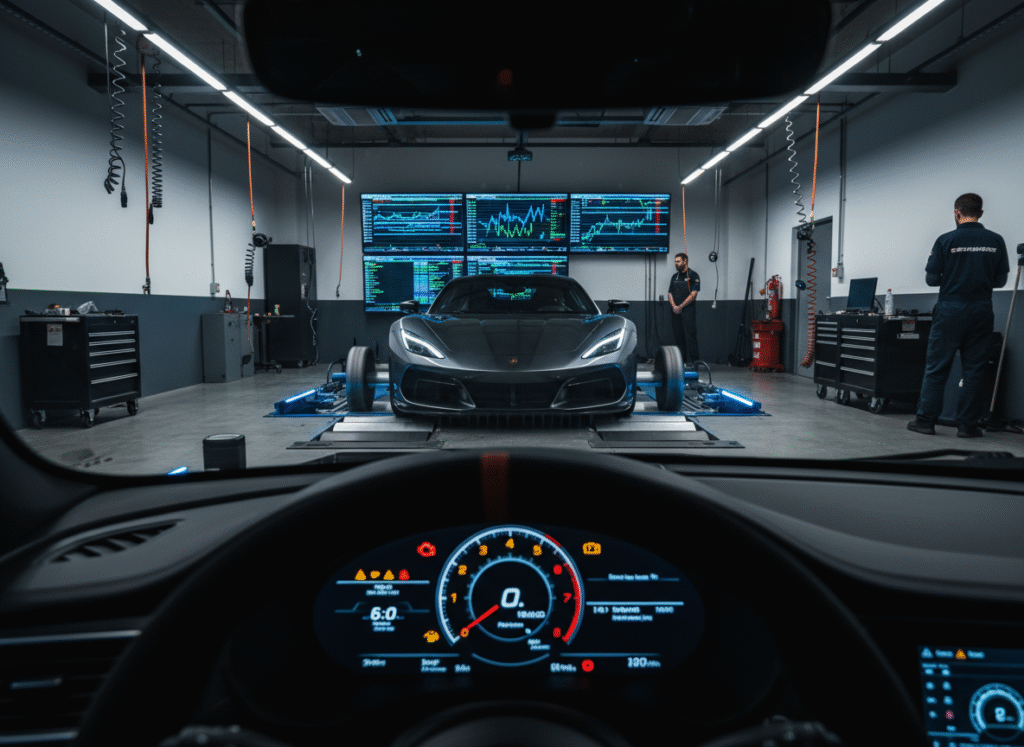

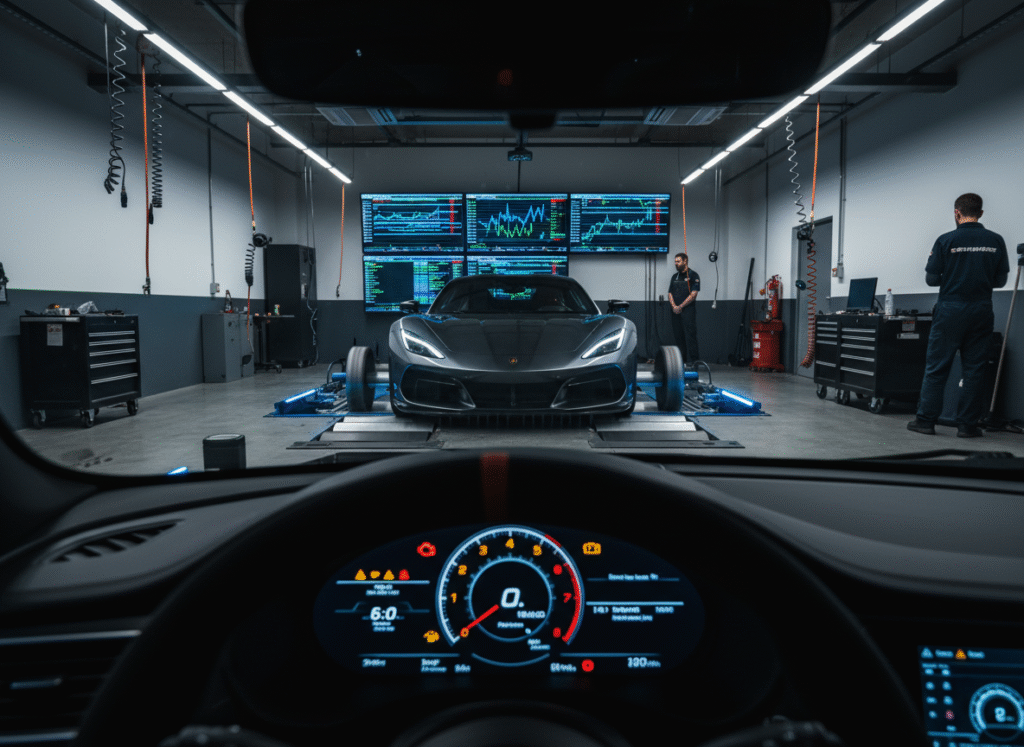

Integration with Other Technologies

Modern vehicles often integrate EGR systems with other emission control technologies, such as selective catalytic reduction (SCR) and diesel particulate filters (DPF). This holistic approach to emission control ensures that vehicles meet stringent environmental standards while maintaining high performance and efficiency.

EGR in Electric and Hybrid Vehicles

While traditional EGR systems are used primarily in internal combustion engines, the principles of exhaust gas recirculation can also be applied to hybrid and electric vehicles. In hybrid vehicles, EGR systems can help optimize engine performance and reduce emissions during periods when the internal combustion engine is in use. For fully electric vehicles, advancements in battery technology and other emission control strategies continue to evolve, reducing the need for traditional EGR systems.

Future of EGR Systems

Technological Advancements

The future of EGR systems looks promising, with ongoing research and development aimed at further improving their efficiency and reliability. Innovations such as electronically controlled EGR valves, advanced materials for EGR coolers, and integration with advanced engine management systems are expected to enhance the performance and durability of EGR systems.

Regulatory Trends

As environmental regulations become increasingly stringent, the role of EGR systems in meeting these standards will continue to grow. Governments worldwide are implementing more rigorous emission standards, driving the need for advanced emission control technologies. EGR systems, combined with other technologies, will play a critical role in ensuring that vehicles comply with these regulations.

Industry Adoption

The automotive industry’s adoption of EGR systems is expected to increase, driven by the need to balance performance, fuel efficiency, and environmental impact. Manufacturers are likely to continue investing in research and development to create more efficient and reliable EGR systems, ensuring that vehicles remain compliant with evolving emission standards.

Conclusion

Exhaust Gas Recirculation (EGR) systems are a cornerstone of modern automotive technology, offering significant benefits for both car performance and the environment. EGR systems play a vital role in creating cleaner and more efficient vehicles by reducing NOx emissions, enhancing fuel economy, and improving engine performance. As technological advancements and regulatory trends continue to shape the automotive industry, the importance of EGR systems is set to grow, contributing to a sustainable future for transportation. Regular maintenance and the adoption of advanced EGR technologies will ensure that these systems continue to deliver optimal performance and environmental benefits.